American Bisque Pottery: Guide to History, Value, and Marks

Any pottery that has been burned in a kiln without a ceramic glaze is referred to as bisque pottery. This can be a finished product, such as biscuit porcelain or unglazed earthenware, or a stage in the production of a glazed end product.

Table of Contents

What is Bisque pottery? Bisque Pottery definition

Bisque refers to ceramic ware that has undergone only the initial firing stage. Air drying the clay helps remove water content before the bisque fire. Bisque ware comes in several styles.

It is said to have first become ceramic after being bisque cooked. Unlike greenware, it can no longer be dissolved in water. In most situations, it’s brittle and porous.

American Bisque Pottery History

In 1919, the American Bisque Company was founded in Williamstown, West Virginia. B. E. Allen, a co-owner of the Sterling China Company, purchased American Bisque in 1922.

American Bisque extended its product line under Allen’s leadership to include cookie jars, ashtrays, dinnerware, kitchenware, lamp bases, planters, and vases, among other items.

The factory of American Bisque was destroyed by a flood in 1937 and a fire in 1945. Even though the building was restored twice, the majority of the company’s historical records were lost.

American Bisque partnered with a few other pottery companies, including American Pottery Company in Marietta, Ohio. B. E. Allen’s son has a stake in American Pottery. At the time of the acquisition of American Pottery in 1944, Joseph Lenhart was also the sales manager for American Bisque. The ceramic molds were purchased from the Ludowici-Celadon Company in New Lexington, Ohio when it reverted to its roofing tile business.

Due to a continuous drop in demand for house design, the firm was financially stressed. In 1982, Bipin Mizra purchased American Bisque from the Allen family. The name of Mizra was changed to American China Company, and the company’s focus moved to the production of dinnerware for aviation institutions. In 1983, the facility was entirely shut down.

American Bisque Pottery Marks

According to WorthPoint, Most American Bisque pieces include a “U.S.A.” marking on or near the bottom of the item. An incised mold number can be seen in rare instances.

On certain items, the initials “ABCO,” “A.B.Co.,” or “ABCo.” appears. While there are no official records of this milestone, American Bisque is the owner of a trademark with the initials AMBISCo WARE.

Cookie jars often have a distinctive logo consisting of three square blocks with the initials A, B, and C.

How Bisque Pottery is Made? What is Bisque Pottery Made out of?

Slip casting is an excellent method for creating complicated forms. It may also be utilized for small-scale item manufacture or limited-edition object creation.

- Slip Casting

A layer of liquid clay “slip” is put into plaster molds and allowed to dry. This is referred to as the ‘cast.’ The clay will begin to absorb water from the casting slip as it covers the inside surface of the mold, which is absorbent. Excess slip is drained out of the mold, leaving just the casting ‘skin’ in the mold. It will continue to dry and shrink away from the mold over time.

- Greenware stage

At this stage, the item is ready to be trimmed neatly before it is allowed to dry fully before being fired.

- Bisque stage

Bisque refers to a piece of greenware that has been burned. The object has been made porous in preparation for painting and glazing.

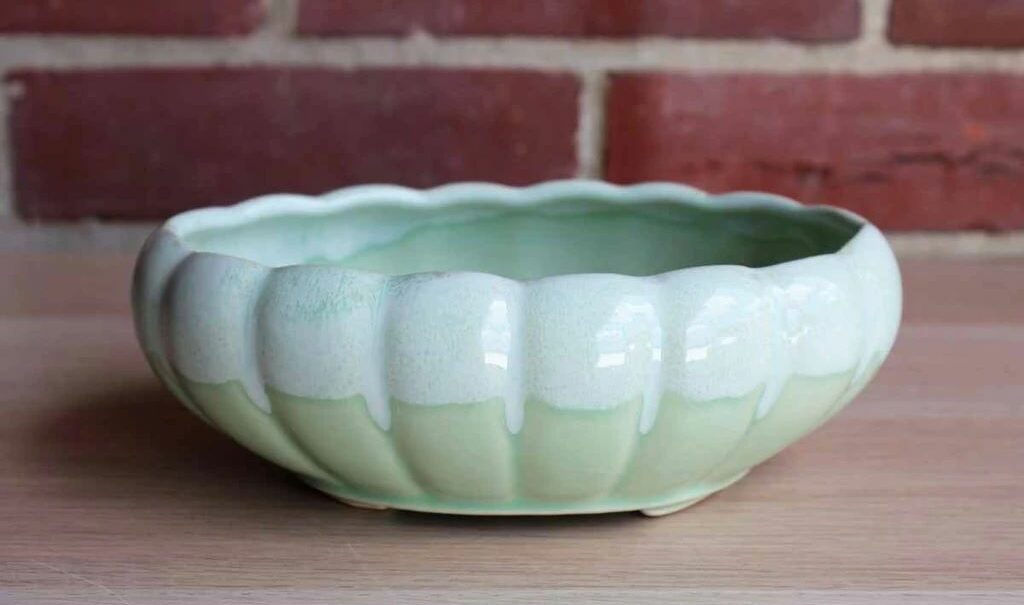

- Glazing and Design stage

This is the stage where the glazing is done, and also the painting and designing of the product.

- Final firing stage

This process ends with fire glazing. This further hardens the product.

Pottery Bisque Firing Temperature

The bisque firing temperature is generally between 900 and 1100 degrees Celsius. A bisque firing is a low-temperature, slow-burning process that seldom reaches 100°C per hour.

If the rise or ramp rate of fire is too quick in the early stages of bisque, the piece may fracture or burst. The final temperature of the bisque firing will be determined by the degree of porosity required.

The greater the temperature, the lower the porosity, and vice versa.

Pottery Bisque Firing Schedule

“Firing ramp” and “firing schedule” are two phrases that are often used interchangeably. Both phrases refer to how quickly the fire is put out, including heating, soaking (if necessary), and cooling. The firing schedule is critical when it comes to bisque firing. Each kiln is unique, but in general, the firing sequence should look like this:

- Warm-up at a low temperature overnight

- Two hours at low heat (no more than 200°F per hour rise in temperature)

- Two hours at medium heat (no more than 300°F per hour increase in temperature)

- Two hours at high heat (no more than 300°F per hour increase in temperature) until the desired temperature is achieved.

Pottery Bisque Glazing

This entails the following steps:

- Thoroughly combine your glazes

- Sand off small bumps using sandpaper

- Waxing the rim and base

- Pour each glaze into its container

- Glazing delicately

- Pay attention to the finer points

- Finishing the appearance with overglaze

How to clean Bisque Pottery?

Before you begin, gather the supplies you’ll need. A clean surface should be set aside for a bucket of water, your bisque-fired pots, a melamine-foam cleaning sponge, scissors, a standard round studio sponge, a paintbrush for underglaze application, waterproof 220-grit sandpaper, and your colorant of choice.

Completely submerge and remove the bisque-fired pot from the pail of water, one piece at a time. Also, soak the sandpaper in water. Start by lightly sanding the pot’s surface while standing over the bucket until it is smooth.

Next, use underglaze or oxide to gently wash the areas you want to emphasize. Using scissors, cut the melamine-foam cleaning sponge into four equal half. Each quarter should clean a handful of pots, depending on the size, clay, and pressure used.

How to Repair cracks in Bisque pottery?

Make paper clay from your clay body. Add a few drops of clear glaze and some finely powdered bisque to the same clay as the cup. Remove any dust from the chip and coat it in a clear glaze. As it dries, it may open up some cracks, but keep filling them with paper clay.

Is Bisque pottery waterproof?

Bisque firing technique pre fires glazed pottery to make it water-resistant, break-resistant, and absorbent for glaze application. Bisque can be painted with ceramic glazes or underglazes, baked, and then used in the water. Thus, Bisque pottery is waterproof.

Conclusion

Examine the base design when attempting to identify a piece of American Bisque pottery. Two large, unglazed wedge shapes can be found at the bottom of most American Bisque pieces. Smaller items may have a solid unglazed base, but this is not a feature of every piece.